On Sunday night, the Alguita ORV left Long Beach Harbor for its six week expedition to study the effects of plastic on the marine environment. They will spend 4 weeks in the North Pacific Gyre resampling areas which were previously sampled on prior expeditions.

Earlier in the week, I delivered the Robodox OpenROV to Dale Selvam , the coskipper of Alguita along with an operational manual and we did some final operational trials in the water behind the boat.

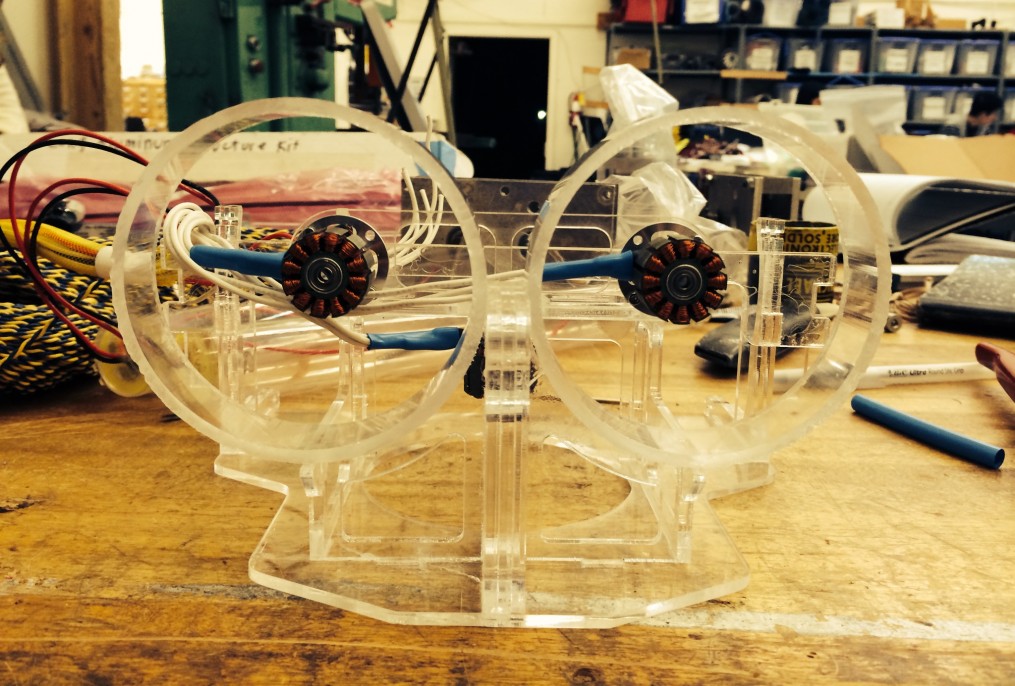

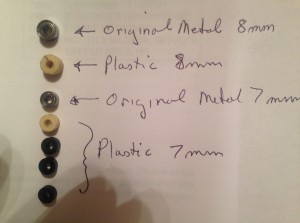

The ROV has several upgrades to make it more user friendly and seaworthy. We added a wireless TP-LINK to the tether, dipped the motor cores in epoxy and replaced the metal motor bushings with plastic bushings. See this post. Software mods were made to keep disconnects from occurring with power surges and also changed the turning power settings to make it more controllable during station keeping maneuvers.

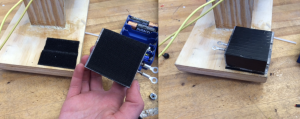

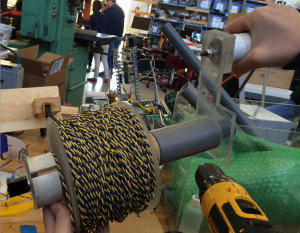

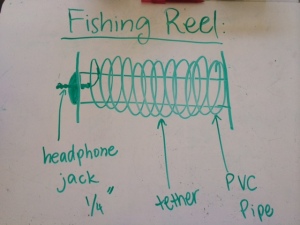

I added a small TP-LINK/Topside adapter Pelican case that can be held firmly in place with an O-ring elastic to a special slideable aluminum bracket attached to the tether reel base. See the following pictures: Note the laminated IP cheat sheet pasted to the inside of the Pelican case.

Ship to Shore:

Be sure to take advantage of the free ship to shore program that allows students and faculty to interact with the crew during the voyage.